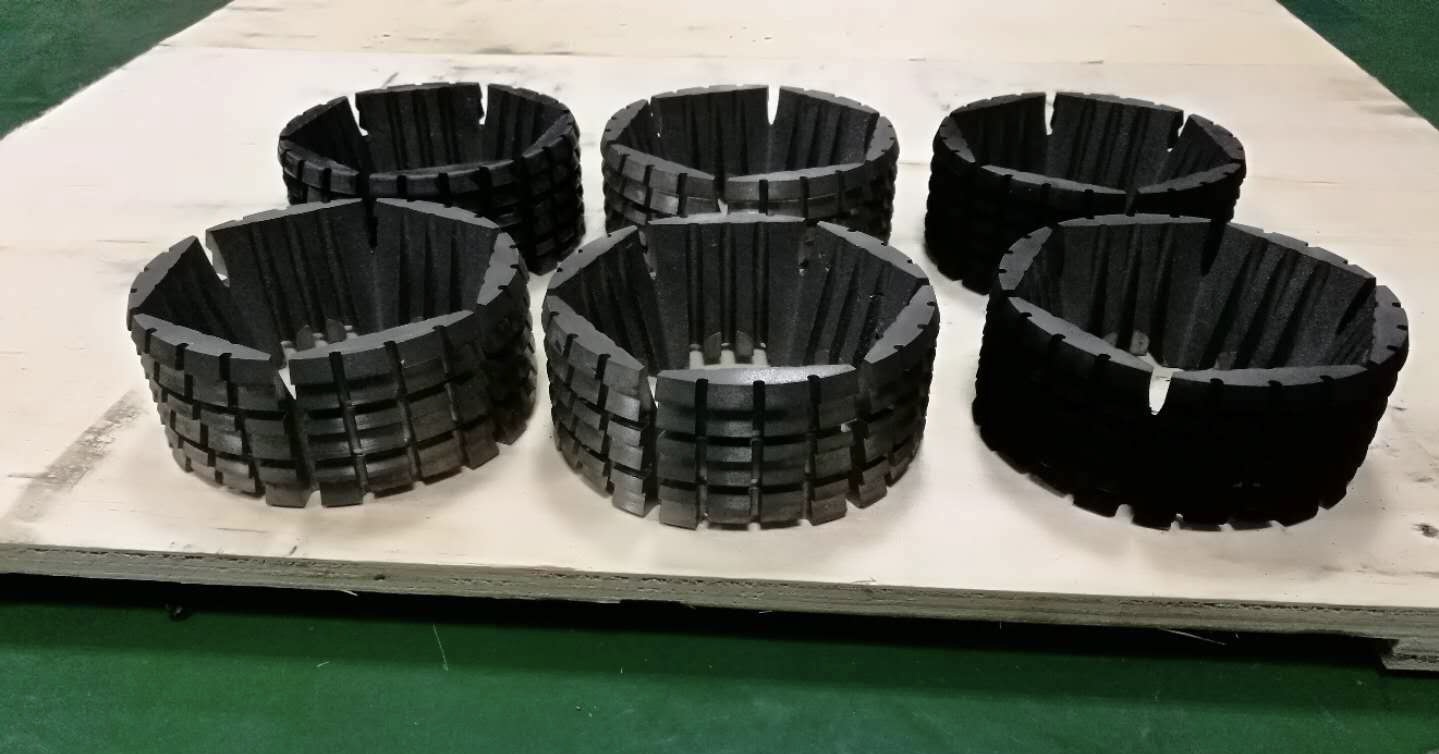

LASER CLADDING

Unlike traditional laser cladding methods that operate at lower speeds, the high-speed laser metal deposition performs laser cladding at high speeds, where most of the powder is melted in space. The laser forms a shallower, smaller melt pool on the substrate material, resulting in ultra-fast cooling rates. This imparts a more uniform microstructure to the coating, minimizes residual stress and reduces thermal impact on the substrate.

The unique melting and solidification characteristics of the metal powder used in ultra-high-speed laser cladding can even produce some coating materials that are difficult to achieve with traditional laser cladding, such as intermetallic compounds, amorphous materials, metallic glasses, and high-content metal composites.